Energy efficiency of a building is important for several reasons. It determines the building’s value on the market. People prefer energy efficient buildings because they have lower running costs. Last, but not least, building energy efficient buildings contributes to better and more sustainable environment – for example, buildings account for 39% of CO2 emissions in the United States!

Why shape affects building’s energy efficiency

Heat will gradually make its way to the outside of the building through building’s external faces (e.g. walls, roofs, terraces). The larger the area of external faces, the more place heat has to escape to the outside. In principle, to minimise heat transfer through the building’s external faces, the building shape should be as compact as possible (similar to a cube).

Sustainable design

Energy efficient buildings don’t need to look boring. Inefficient features can often be avoided or replaced by alternatives which are still architecturally interesting. For example, recessed doors could be replaced by canopies over the entrance, and a similar ‘feel’ to bay windows could be achieved with window seats and alternative window reveal detailing (source).

Figure 1: Compact buildings do not need to be ugly (photo by Vecislavas Popa).

Comparing the energy efficiency of different design solutions should ideally be done in the early design stage as making changes later can be very time consuming and expensive. One option to improve building’s potential to save energy in early design stage is by calculating Form Factor of the buildings.

How to calculate building’s Form Factor

We can calculate Form Factor in different ways. Here we present two ways that are most commonly used nowadays. But first let us define the term building’s envelope area. Building’s envelope area is the sum of areas of external faces of the building (e.g. walls, roofs, terraces).

Note: If we needed to make detailed calculations, we would have to know the building’s thermal envelope area – the sum of the building’s insulated faces. The insulated faces form the main barrier for the heat. A building with an insulated ceiling has a lower Form Factor than the same building with insulated roof pitch (source). That is simply due to a pitched roof having a larger surface than the flat ceiling.

Heat Loss Form Factor

Heat Loss Form Factor (HLFF) is the ratio between the building’s envelope area (EA) and it’s net floor area (NFA). It is calculated as HLFF = EA / NFA.

This definition of Form Factor was used in a report The challenge of shape and form, published by British National House-Building Council in 2016.

HLFF is a number generally between 0.5 and 5, with a lower number indicating a more compact building. Passive houses aim to achieve HLFF 3 or less.

It is quite difficult to get a form factor below 2.5 on a stand-alone residential building (source). For example, a compact square 2-storey building with a 10 x 10 m² floor plan, still has a form factor of 2.97.

Larger buildings, however, can achieve an even better form factor. For example, a compact 4-storey block with 16 x 32 m² floor plan has a HLFF of 1.44. A 20-storey skyscraper with 20 x 20 m² floor plan has a HLFF of 0.76.

Surface to Volume Ratio

Another common way to calculate Building’s Form Factor is Surface to Volume Ratio (SVR). SVR is the ratio between the building’s envelope area (EA) and it’s volume (V), it is calculated as SVR = EA / V.

Note that the numeric value of Surface to Volume Ratio depends on chosen dimension units (eg. meters, feet).

This definition was used for example in German Energy Saving Ordinance, which sets the requirements for the total primary energy demand of the buildings by the Form Factor.

The Surface to Volume Ratio for a typical single family house is 0.8 – 1.0 1/m (0.24 – 0.3 1/ft). According to some sources, the recommended Surface to Volume Ratio for a passive house is ≤ 0.8 1/m; according to another source 0.5 1/m (0.15 1/ft) (source).

Like with the Heat Loss Form Factor, larger buildings can achieve better Surface to Volume Ratio than smaller buildings. The main reason for this is purely geometrical. Larger geometric bodies have a lower surface area to volume ratio than smaller geometric bodies.

Let us use the same examples as for Heat Loss Form Factor: a compact square 2-storey building with a 10 x 10 m² floor plan has a Surface to Volume Ratio of 0.771 1/m (0.23 1/ft). A compact 4-storey block with 16 x 32 m² floor plan has a SVR of 0.37 1/m (0.11 1/ft). A 20-storey (h = 60 m) skyscraper with 25 x 25 m² floor plan has a SVR of 0.2 1/m (0.06 1/ft).

Comparison

The two ways to calculate Form Factor were compared in the paper Shape Factor as an Indicator of Heating Energy Demand by professor Kimmo Lylykangas from TalTech University. The results show that Heat Loss Form Factor is more accurate when comparing buildings with different heights. When the height of the space increases, the volume and the heating energy demand grow. Surface to Volume ratio falsely indicates that the building got more compact and therefore needs less energy than lower building. Heat Loss Form Factor on the other hand shows relatively good correlation with the simulated heating energy demand.

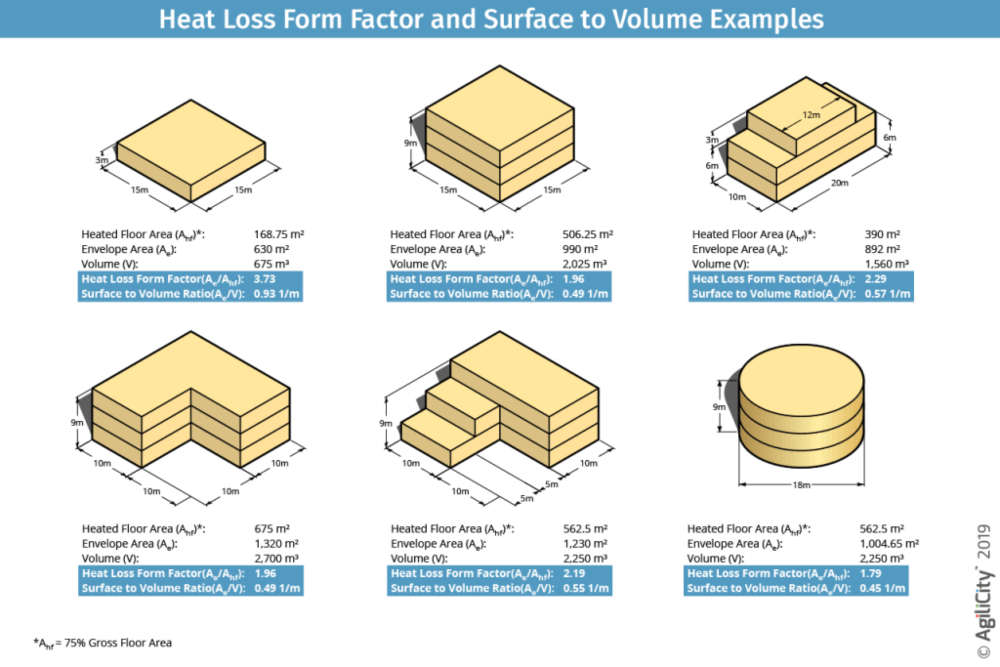

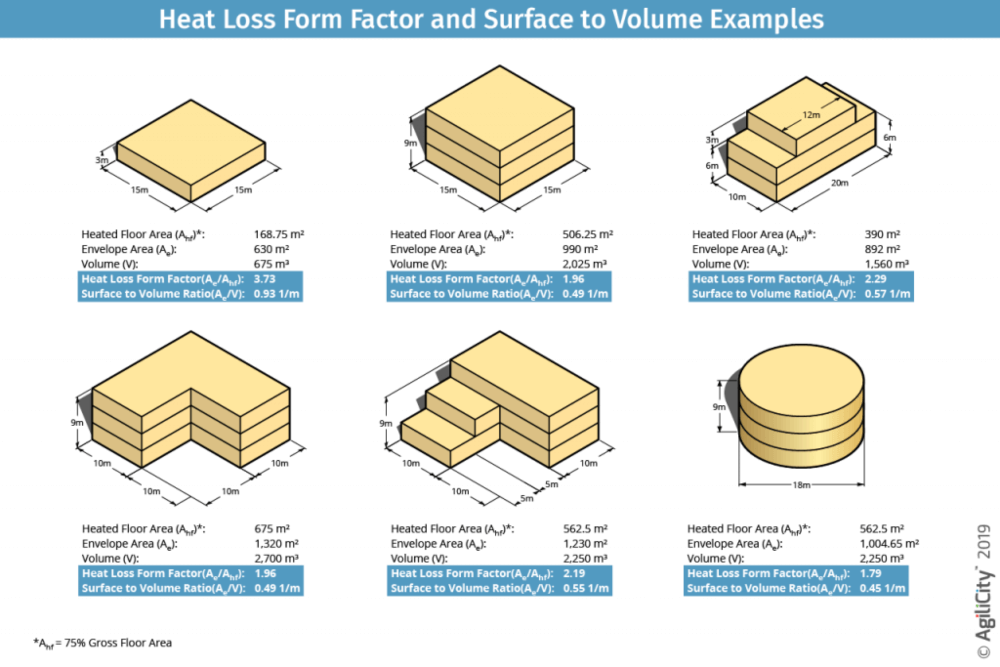

Figure 2: Example of different Heat Loss Form Factors and Surface to Volume Ratios based on different building shapes. You can download PDF image here.

Compare the Heat Loss Form Factor and Surface to Volume Ratio of the first two buildings. Although they share same floor plan, creating building with 3 storeys instead of 1 results in almost 50% better Form Factor and Surface to Volume Ratio. In the last two examples, you can see that both buildings that share the same Heated Floor Area differ by about 20% in Form Factor and Surface to Volume Factor.

How to incorporate Form Factor into your design process?

You can always calculate Form Factor by extracting heated floor area, envelope area and building volume from your favorite CAD application and do the required calculations manually. But this can be very time consuming, especially when it comes to validating different design alternatives.

It is thus better to use an appropriate software that does the work for us. One such example is Modelur software, which can calculate this automatically. This makes it a lot easier to compare different design alternatives in terms of Form Factor and Surface to Volume Factor. You can request free trial license here.

Benefits of considering Form Factor

Form Factor alone is not completely accurate energy consumption indicator, especially for buildings with complex plans. Other factors, such as the direction and speed of winds and amount of solar radiation, affect energy consumption, too.

But Form Factor can give a good estimate of building energy demand in the earliest stages of design process. Knowing Form Factors of different design solutions, allows us choose the one that is the most efficient. This way we can reduce heating (or cooling) demand of new buildings significantly – in some cases even up to 50% (source) – at practically no extra cost.

There are also other benefits of considering Form Factor. Buildings with better Form Factor often require less insulation and construction materials than buildings with poor Form Factor. This leads to win-win situation, where we can save money and reduce carbon footprint of the building by just choosing the design solution with better Form Factor.

If you wish to stay updated with our news and interesting posts like this one, please follow us on LinkedIn.

—

About AgiliCity

AgiliCity is EU based startup developing urban design software Modelur that helps urban designers work more efficiently. More than 60 customers like Gensler, Atkins and CallisonRTKL rely on our technology to reduce costs, maximize development potentials and deliver their projects faster. AgiliCity is a proud member of Arcadis City of 2030 Accelerator, powered by Techstars.

4 Responses

Great post! Has there been any comparative studies done of actual savings on operational costs for buildings constructed with low heat loss factors versus those using traditional single story squared plans? I am thinking this would be especially interesting to those developing commercial tilt up concrete office buildings.

Hi Nate, thanks for your comment. This paper (which is one of the best we found on the topic) claims that heating bills can be even halved (page 2). It also includes comparison of different buildings types. But most of the papers we read about this topic state that the actual difference is somewhere between 10-20%. Still not bad (for costing nothing)!

Thank you for the insights!

I have a question: how do you calculate the surface area of the envelope in case of a building located between two buildings (Row building)? Heat losses only occur with the surface areas which are exposed to the exterior. This means that the formulas should be:

S/V = (Exposed) surface area of the envelope / Volume of the building

Is that correct?

Thank you

Hi Dang,

Thank you for your comment. You are correct, when talking about row buildings, overlapping walls shouldn’t be added to the calculation. In fact, they usually are a single wall shared between two units. In such cases we reccomend you to combine row buildings into Modelur’s Complex Building. This way, when calculating envelope area, Modelur takes care of these parts of the building so they are not accounted for. Note that for now, you need to be precise when putting buildings together in order for Modelur / SketchUp to do its work properly in such cases.

Best regards,

Jernej